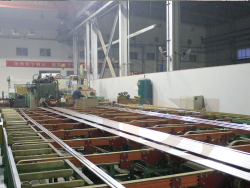

The company possesses extrusion and die casting equipment varies from 630T to 3000T, a whole industry chain from alloy production to final products, 20000T magnesium alloy extrusion profile and die casting products per year, and a capacity of 20000T alloy billet per year.

With the development of the company, by increasing the R&D investment and strengthening team building, enhancing the combination of production, learning, research and utilization, we realized serialization, standardization and specialization of product production, mastered the generic technology and key technology for magnesium alloy billet production to extrusion, which enables our company to keep in the front rank of counterparts in the respect of new alloy development, magnesium alloy extrusion process automation, extrusion mould specialization design, magnesium alloy extrusion integration technology, industry chain standardization system and overall quality management system building. We have obtained 39 patents for utility model and national invention and applied in our production. These patents are powerful guarantee of our company’s continuous development and growth. We are leading the way in industrialize production of high-performance extrusion magnesium alloy billet, ultra-thin magnesium alloy tube, high precision magnesium alloy industrial profile, high performance leisure products profile and etc.

Tianjin Dongyi owns several major product series, like magnesium alloy extrusion profile, magnesium alloy die casting product, magnesium alloy sacrificial anode, high pure magnesium and magnesium alloy billet.